PHYSCI 70: Introduction to Digital Fabrication

Marie Konopacki

Week 3

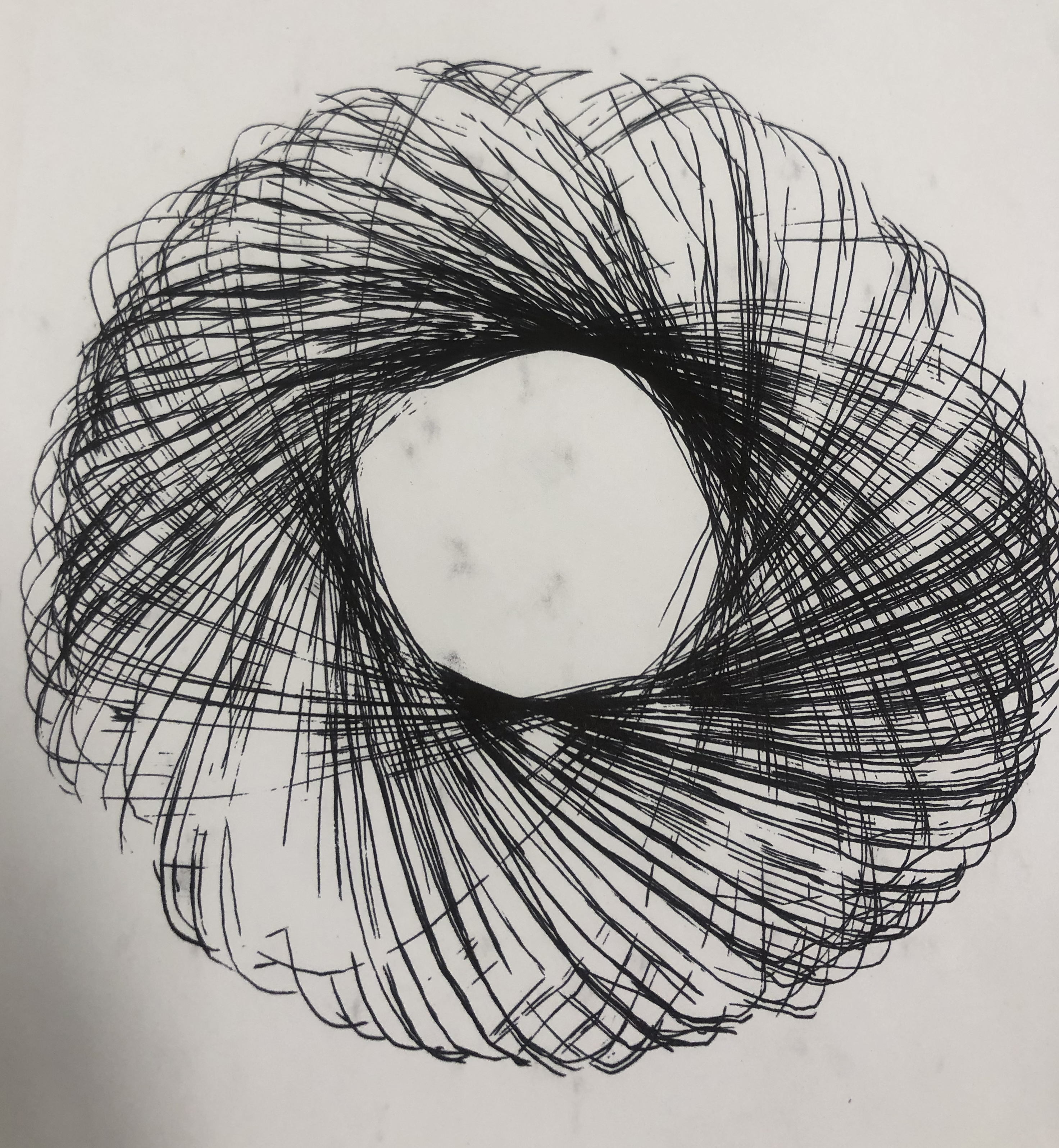

This week, we were instructed to create a kinetic sculpture with both a static joint, a prismatic or revolute joint, and optional circuitry. I spent some time brainstorming what exactly I would want to make, since I knew that I wanted it to not only be a sculpture but complete a function. I eventually landed on the idea of automating a spirograph (video to the left). Essentially, a spirograph is a tool that creates a rotational patten by using a gear turning inside of a larger gear.

I created the top and bottom of frame by designing it on both Fusion 360 and Adobe Photoshop and then laser cutting it. I bent and sawed wire to create the mechanism that connects the motor to the gear, and I used hot glue to connect the wire directly to the motor. I did this because hot glue is fairly flexible, and I knew that if I made any mistakes it was easily undoable. One of the greater challenges was calibrating the gear’s movement, since at first it only connected with the larger gear for only about 75% of its revolution. This was because the gear was essentially free-floating; it relied solely on the metal wire to provide enough tension to push it against the larger gear. I made micro shifts to the motor’s vertical and horizontal positioning on the frame as well as the gear’s rotational speed to ensure that eventually the smaller gear touched all sides of the larger gear.

I’m pretty satisfied with the end result. Although it certainly isn’t perfect, I was able to create a sculpture that makes its own works of art!